Commercial industrial humidifier used in industries factories: agriculture, printing shops, paper storage, tobacco, food storage, by Air Force Base to humidify the hangers for the B-2 stealth bombers. Another major account, Walmart, uses them to maintain large produce transfer facilities.

Alcoa uses them to cool down large aluminum blanks. Oil companies use explosion-proof XE's on oil rig platforms to cool down the drilling crews. Owens Corning, Ernest & Julio Gallo, and Gibson Guitars all use commercial humidifiers foggers for manufacturing plant air humidification.

Shipped complete, ready for use. Shipped in box, by Tracking Co. right to the door, safe, insured no damaged.

Industrial Humidifiers Collection HERE

Other specialty applications include:

- Odor Control

- Large Munition Storage

- Tobacco Conditioning

- Wine Storage

- Large Printing Operations

Industrial portable humidifiers increase air humidity level, this is especially important for concrete curing, to focus on maintaining humidity to achieve high strength concrete.

Products in a 100% humidified concrete curing chamber are able to retain their moisture, increasing chemical reaction and heat generation. In many cases, the heat generated will be sufficient to maintain the chamber’s targeted temperature range.

Industrial Commercial Humidifiers Collection HERE

It’s all about performance and reliability in this extremely harsh, high RH environment. Portable humidifiers Turbo XE's have been proven in curing room chambers across the country.

Common uses

- Concrete Curing Pipe

- Precast Products

- Aviation Hangers

- Block & Pavers

- Core Testing

- Oil Industry

- Tobacco

- Agriculture Greenhouse

- Warehouse Humidification

- Static Electricity Control

- Dust Control

- Decorative Molded Shop

Industrial Commercial Humidifiers Collection HERE

Still using "old school" steam curing? Many products cure unevenly with steam, and it's related to where they are placed within the cure room. Steam rises when it enters a chamber, then condenses as it cools to ambient temperature. This can result in wetness up high and uneven temperatures from top to bottom. The physics of steam make the cure room’s environment difficult to control.

To gain control of conditions and even out the environment, consider using Turbo XE's for humidification, combined with additional heat as needed. Not only will you experience more consistent curing, you'll reduce energy costs too!

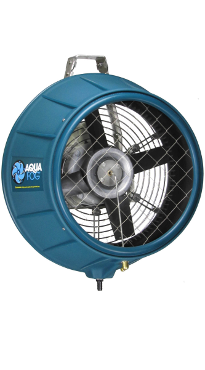

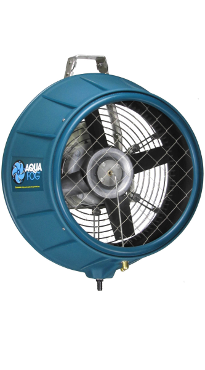

The system design with a float valve in the water tank, for automatic water refill, and maintain the water level in the water tank. A special submersible pump in the water tank, to feed the fogging head, and Ball Valve to control the fogging density output, Baldor (r) Wash-Down-Duty(tm) Motor Industrial Grade motor for pressurized water use, power-coat Epoxy finish, stainless steel shaft.

Industrial Commercial Humidifiers Collection HERE

Industrial Humidifiers Collection HERE

Humidifier Designed with castor wheels for easy mobility, portable ease of move and use.

Tank holds up to 18 gallons for convenient portable use. Or can be attached with garden hose connect to an ordinary water supply for long-term operation.

Humidifier Include: Float Valve in the water tank for automatic water refill and maintain the water level in the water tank. Four Position Pivoting Fogging Head. On/Off Power Switch. 20 feet long Power Cord with plug. Garden Hose Connection. 1/4 Turn Ball water valve to control GPH ( water gallons per hour ). Capacity up to 32 GPH. Nozzle-Free Atomization. Pivoting Fogging Head. Recycles waste water. Baldor (r) Wash-Down-Duty (tm) Motor Industrial Grade with stainless steel shaft. Rolling castor wheels. Arrives safely packaged, impact protected and fully assembled. Ready for use.

Standard Controls and Features:

Float valve auto water refill - maintain water level in water tank, large tank lid access, fluid level gauge, in-line strainer, Water -tight NEMA 4x, Stainless steel, Brass Polyethylene, Garden hose connect. Rolling castor wheels. A 1/4 turn Ball Valve Control flow rates and fogging density output. Lower flow rates are generally used in applications requiring drier fog.

Industrial Commercial Humidifiers Collection HERE

Flow Rate with Related Applications:

Up to 32 GPH - Ag/Horticulture, Evaporative Cooling, Concrete Curing, Mushrooms

Up to 15 GPH - Manufacturing Plant, Wine/Barrel Storage, Wood/Lumber/Paper, Textile, Agriculture

Up to 8 GPH - Mfg Dust/Static, Textile Plant, Tobacco, Produce, Printing Shops

Up to 2 GPH - Odor Control

Baldor (r) Wash-Down-Duty (tm) Motor: Industrial Grade For Pressurized Water Use, Powder-Coat Epoxy Finish, Stainless Steel Shaft

Specifications:

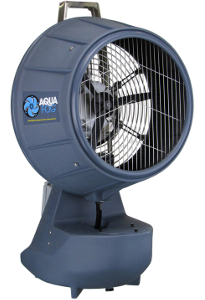

Dimensions:

Length 25.5 in / 65 cm

Width 21 in / 53 cm

Height 44 in / 112 cm

Approximate Weight: 76 lbs / 36.3 kg

Approximate Shipping Weight: 122 lbs / 57.6 kg

Propulsion Distance: 30 - 35 ft/ 9.1 - 10.5 m.

Fogging Head Pivot Angle: 0, 15, 30, 45 degrees

Main Motor:

Jaybird’s Rear-Feed Blade

Our exclusive blade design is a significant product development, enhancing reliability and performance.

ABB Wash-Down-Duty Motor

- Industrial grade

- For use around water

Noise @ 10 ft distance:

1HP - 7.8 amps @ 115V (60Hz)

1hp units, 73 dB(A)

Average Particle Size:

5-10 microns @ low volume

25 microns @ mid volume

35 microns @ high volume

Tank Capacity: 18 US gal / 68 L

CFM: 3,200

Hardware: 300 Series stainless steel

Environment:

Endures temperatures from

33F to 160 F

Indoors / outdoors

Humidity to 100% RH

UV stabilized & impact resistant

Extra Automatic controls optional - select bellow when ordering:

If the tank's fluid level gets low, the unit will shut down. This custom feature is not compatible with automated controls. If you are planning to automate your unit using a Humidistat, timer or other controller, then this option will not work. An important add-on feature for certain applications, a momentary push button switch operates the power supply through an electrical relay that is controlled by an internal fluid-level switch. If the unit shuts down, refill the tank and manually push the start button again. Not compatible with automated controls.

Industrial Commercial Humidifiers Collection HERE

Ideal for control of applications requiring 80% or less relative humidity. Incorporates a starter contactor to handle the power load of the XE mobile units. Fast-acting Element, Range 20-80%RH, Rain-tight Enclosure, Differential approximately 7%.

If your primary interest is long cycle operation, the basic 24-hour timer control is a reliable way to automate the XE mobile units. Supplied with male and female cord set, Rain-tight Nema 3 enclosure, Adjustable 1 hour cycles, 2 sets of on/off trippers provided, 115V. 60Hz.

If your interest is in evaporative cooling, the thermostat control is the best choice to automate your XE mobile units, Water-tight Nema 4X, Differential 3 F, Control range 40-110 F, 100- 250V. 50/60Hz.

Ideal for applications up to 100% Relative Humidity. This precision hand-held thermo/hygrometer is ideal for measuring and monitoring ambient and dew point temperatures and relative humidity in a wide range of professional and industrial applications. Dual readout LCD displays in F or C. Temperature range/accuracy: -4 to 122F (-20 to 50C)/1.8F (1C), Humidity range/accuracy: 0 to 100%RH /3% , Response time: 60 seconds, Power source: Two "AAA" batteries (included).

This precision hand-held thermo/hygrometer is ideal for measuring and monitoring ambient temperatures and relative humidity in a wide range of professional and industrial applications. Dual readout LCD displays in degr/F or degr/C, Temperature range/accuracy: 32 to 122 degr/F (0 to 50 degr/C)/1.8degr/F (1 degr/C) ,Humidity range/accuracy: 20 to 95%RH /3%, Response time: 60 seconds, Power source: CR2032 Lithium-ion battery (included)

Energy cost comparison example:

- To maintain a 20’ × 50’ chamber @ 100% RH would require about 15 gal water/hour

- 15 gal × 8 hr/day × 260 business days = 31,200 gal/year

- The cost to steam off 31,200 gal of water @ 7¢/kwh = $ 5,126.85

- The cost to atomize 31,200 gal using Turbo XE @ 7¢/kwh = $ 181.71